Laser scanning

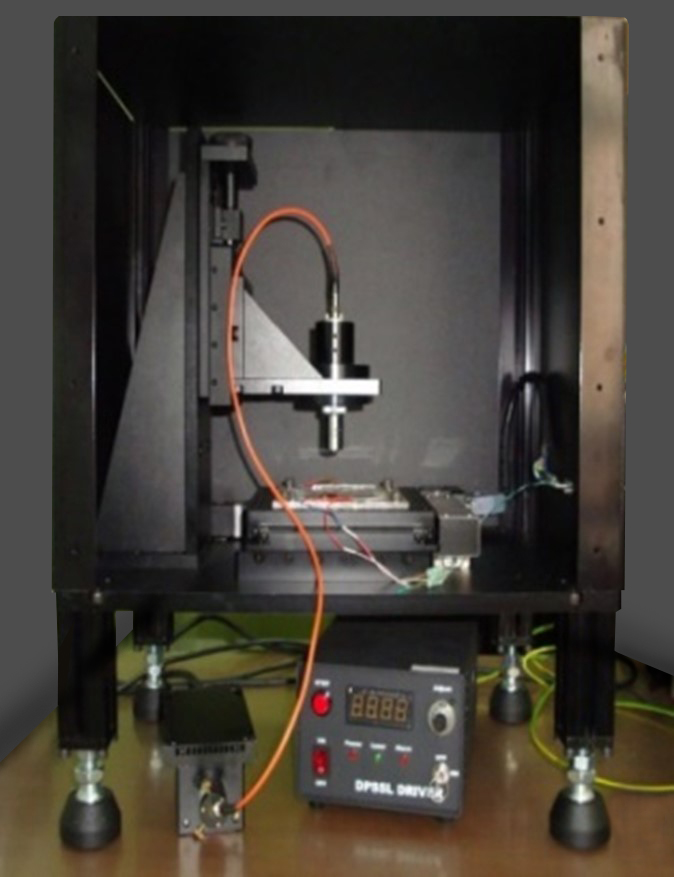

The installation is intended for the qualitative and quantitative analysis of output performance of photoelectric converters.

Characteristics:

- Resolution is 1,25 µm.

- Program laser power control and installation of the position of micrometrical moving appliance.

- Possibility to view an intermediate result during the scanning process.

- Possibility to save experimental results in a binary file and to save as a picture.

Operation principle of the installation

The appliance analyses an electrical signal that is proportional to a photoconductive response of a photoelectric converter whose small area is Illuminated by a laser beam at that moment. The photo converter moves by means of a moving appliance. In other words, an illuminated area and a signal of photo response change. Thus, the matrix is formed from photo responses of each photo converter’s pixel. The matrix is saved to computer memory. By means of the software, the matrix is filtered by range of values each of which is responsible for a specific type of defects. We get several visualization pictures of different types of photo converter`s defects as a result. The appliance can be used for post-manufacturing and final checking while producing photo converters.

|

|

|

|

|

|

|

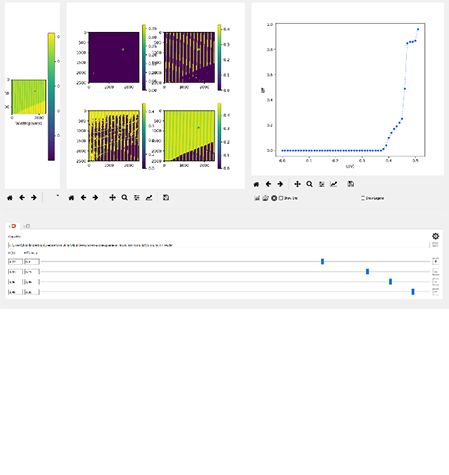

Defects that were detected during a scanning process. |

|

Lithium-ion power sources

The specialists of Keldysh Research Center have been carrying out works on the development and creation of new types of lithium-ion batteries for use in space. One of the developments of a new type based on lithium-ion batteries in a soft polymer package is intended to be used in the CubeSat small-sized spacecraft.

While developing and creating an experimental prototype, new technical solutions were realized as follows:

-

Use of fastening elements made of carbon fiber possessing a high resistance to bending and a little weight.

-

Batteries connection using a scheme that is convenient for connecting diagnostic equipment via a bus.

-

Implementation of the most widespread circuits 3.3V and 5V that eliminates the need for spacecraft developers to stabilize voltage.

Solar arrays

|

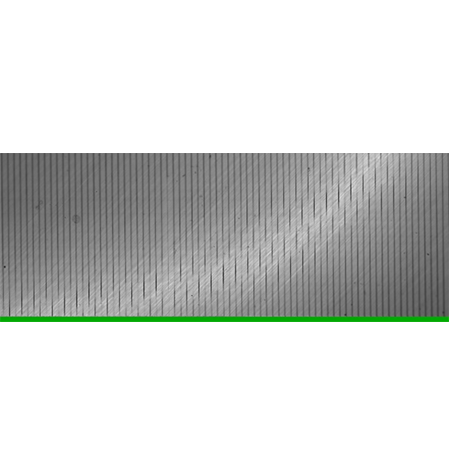

A fragment of a solar array on an ultrathin carbon fiber honeycomb panel. |

|

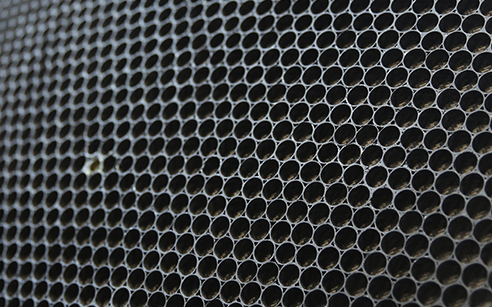

Manufacturing method of a carbon fiber honeycomb core material. Molding process. |

A carbon fiber honeycomb panel was developed and manufactured in order to locate a photogenerating part on it, and to solve actual tasks for manufacturing advanced and compact structures of solar array panels that have the improved energetic specifications, mass and dimension parameters and strength characteristics.

The ultrathin solar arrays based on carbon fiber honeycomb panels are intended to be used in spacecraft and designed to replace solar arrays based on a string frame, as well as Kevlar and aluminum honeycomb core material. Exclusive rigidity and little thickness make it possible to increase the size of a solar array that can be mounted into a nose fairing of the rocket.

Manufacturing method of a carbon fiber honeycomb core material (moulding process) is patented by Keldysh Research Center (the Patent of the Russian Federation № 2623781).