Electric Arc Installations of the Experimental Complex of High-Temperature Tests

Plasmatrons are used in:

-

rocket technology;

-

scientific research;

-

technological processes for the production of new materials, application of coatings;

-

destruction of industrial, domestic and medical waste.

Plasmatron

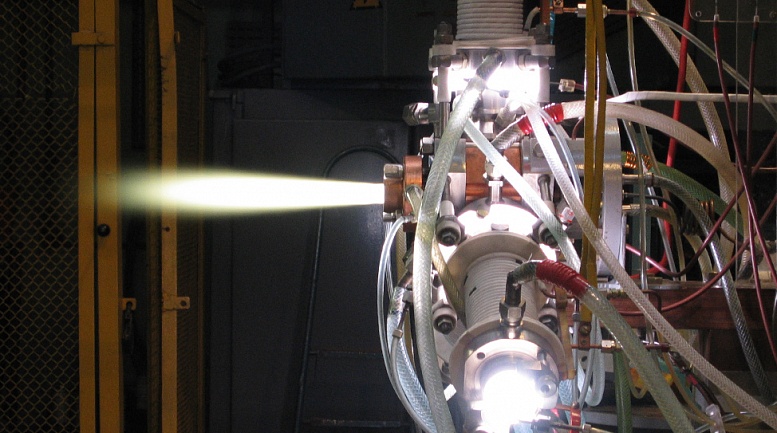

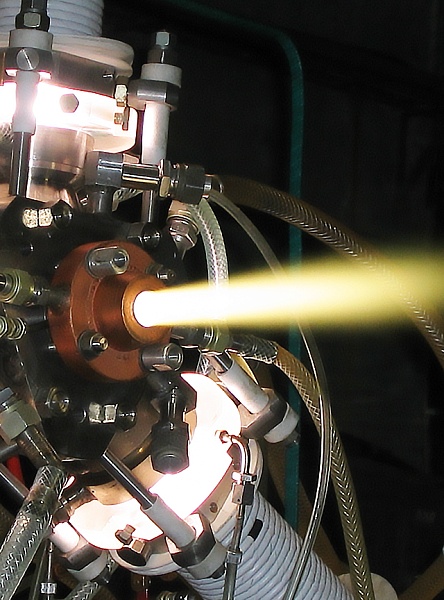

The Zvezda plasmatrons

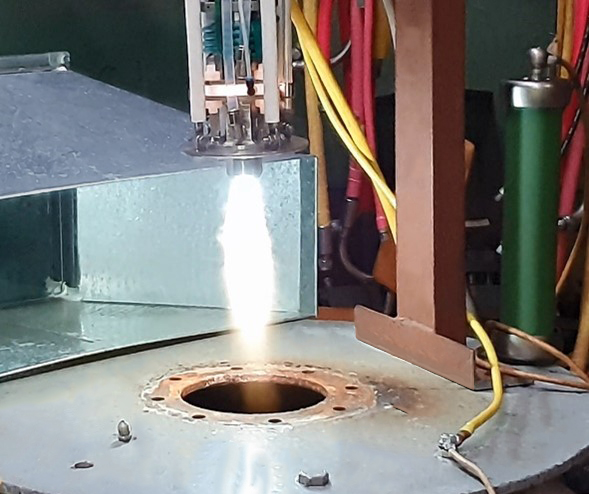

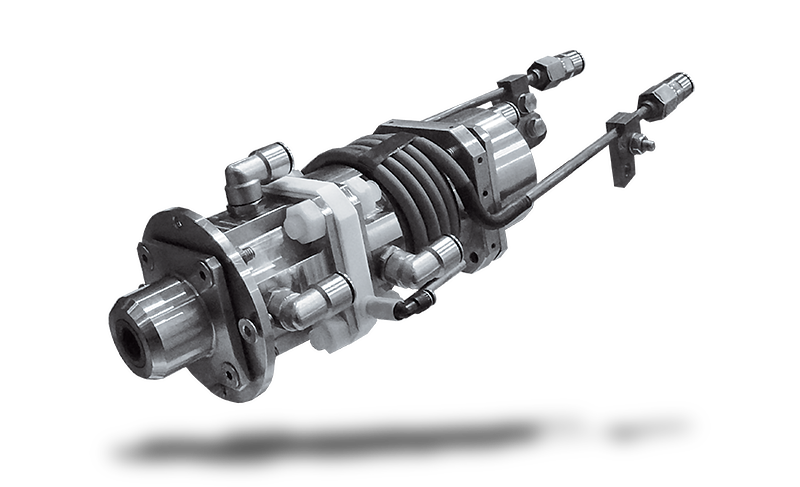

The RG-100 plasmatron

Main advantages

- Power supply from industrial three-phase network, no additional transformers, rectifiers or frequency converters.

- Symmetrical load of three-phase network.

- Long-term continuous operation.

- High reliability.

- Simplicity and convenience of use.

- Modular construction, easy replacement of electrodes.

- Uniform distribution of temperature and pressure at the exit of a nozzle.

- Operation modes adjustment in a wide range.

The plasmatron scheme

The plasmatron operates using a «star» principle. The working gas is supplied into electrode assemblies and it is heated in three- or six-arc discharges connected between themselves inside the plasmatron`s mixing chamber. Vortex and electromagnetic stabilization of arc discharges is applied in this type of plasmatron. Ballast inductance coils are used in order to stabilize arc currents.

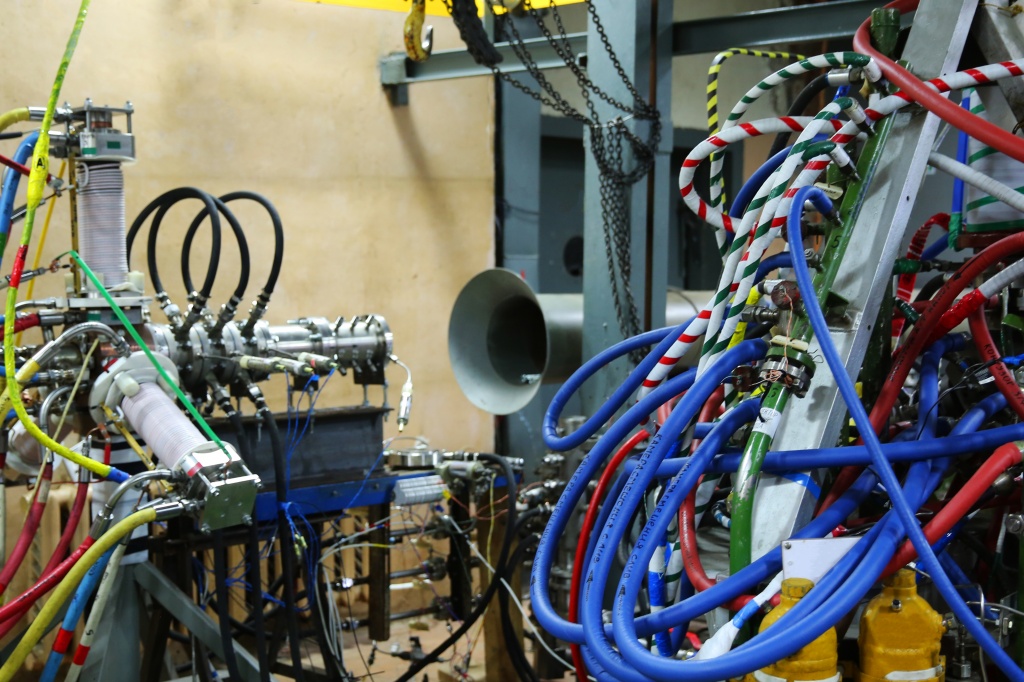

Keldysh Research Center posseses a full cycle of project conception, manufacture and turnkey project delivery of electric arc-heater experimental installations of different power and purpose.

Keldysh Research Center will develop a plasmatron according to your technical requirements, manufacture, and assemble it at your working place as well as put it into operation.

We accept orders for conducting tests on our testing facilities.

The specialists of JSC "Keldysh Research Center" have developed the RG-100 electric arc-heater (plasmatron) with an average power of 30-40 kW and its gas temperature at the exit up to 5500 K. The plasmatron can be applied in the development of new technologies for rocket and space equipment, and in various industries.

Fields of application:

- High-temperature detoxication and waste disposal.

- Production of fine powders of materials.

- Processing or spraying of powder materials.

- In plasma chemistry for carrying out reactions in plasma medium.

- For re-melting refractory and ultra pure materials.

- For firing boiler furnaces.

- Other areas of application.

Technical characteristics:

- Arc power is 30 - 40 kW.

- Heat efficiency is 0,75 – 0,9.

- Pressure in chamber: atmospheric.

- Life time until electrode replacement is 500 hours.

- Arc current is 120 – 180 A.

- Arc voltage is 180 – 300 V.

The RG-100 plasmatron peculiarities:

- Vortex chamber ensures a steady operation mode during the whole period of operating life.

- Control system with the adjustment of current.

- Remote control and adjustment of operation modes.

- Power supply from the 380-400 V network.

- Small dimensions (the length is 230 mm, the diameter is 80 mm).

- Weight is 6 kg.

- Quick replacement of electrodes.