R&D works of JSC Keldysh Research Center are carried out with the use of modern and multifunctional experimental base that is constantly being improved. Test facilities consist of a series of test installations and benches most of which, by their technical characteristics, are the only ones, and they have no analogues in Russia or other countries with a developed rocket and space industry:

- Test facilities for studying work processes and for different tests

- Test facilities, which simulate external impact on objects

- Test facilities for studies, tests and testing of onboard power supply systems

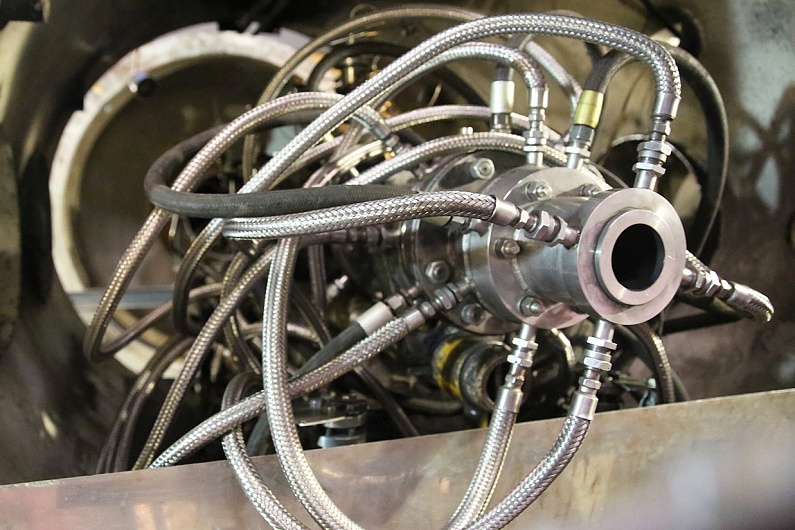

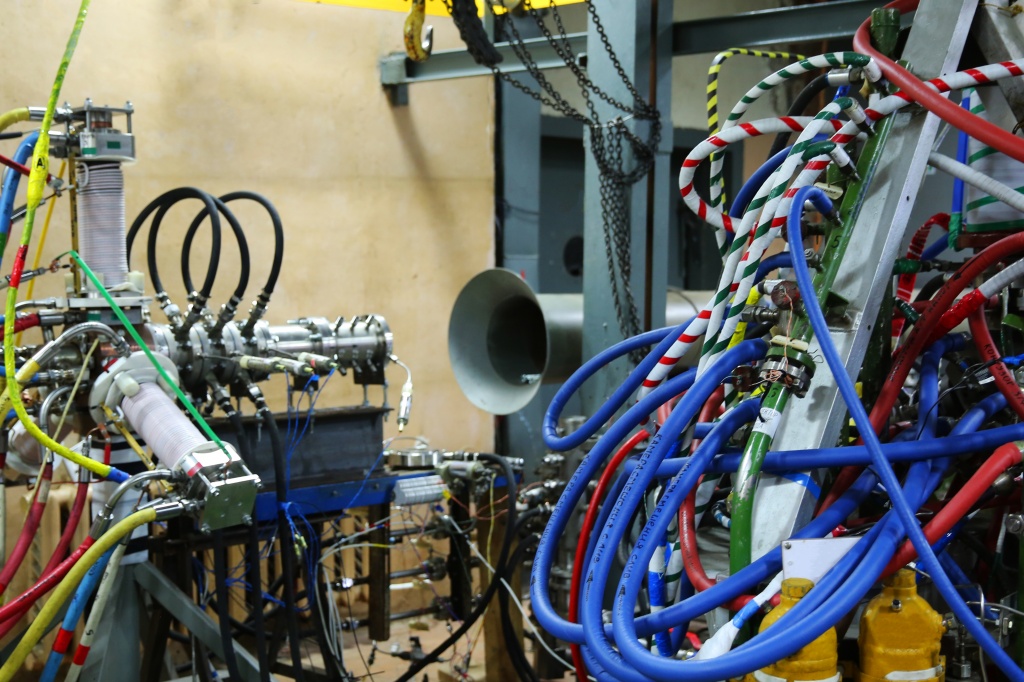

Nozzle differential facility

Model studies of acoustic and vibration characteristics of objects surrounded by a gas flow, including a supersonic stream, are conducted at the facility. The Mach number range of a flow is from 0 up to 8.

Besides that, the ejector systems and noise protection elements are studied and tested.

Propellant: high-pressure air + liquid ethanol

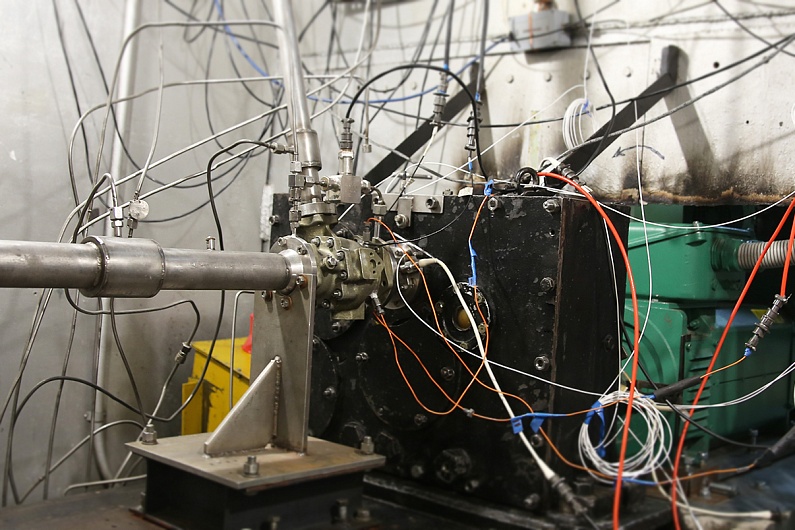

Test facility for investigation of work processes during combustion

Works on the investigation of work processes during thermal transmission and heat and mass exchange are conducted at the facility. Besides that, the materials and coatings properties are studied too.

The experimental research on improvement of protection means against fire of structural materials when heated in an oxidizing environment is also conducted at the facility.

For such studies the following nature components are used:

- Kerosene (naphthyl)

- Liquid methane

- Gaseous hydrogen

- Liquid oxygen

Investigations are carried out on environmentally friendly fuel components such as:

- Gaseous oxygen

- Gaseous hydrogen

- Gaseous methane

- Liquid ethanol

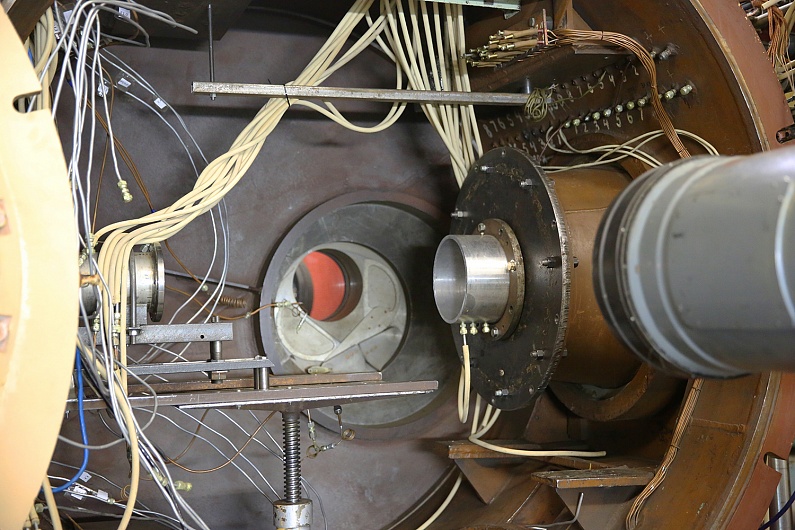

Test facility for studying work processes in pumps and turbines

This test facility includes five experimental test benches intended for:

- autonomous tests

- tests of pumps

- tests of gaseous turbines

- tests of pressure generating devices

- tests of slot and end sealings

Test facility for investigation in the sphere of gas dynamics at high Mach- and Reynolds- numbers

The test facility is equipped with modern measurement systems for slowly changing processes (pressure, flow rate, thrust and temperature) and a modern visualization system of a gas stream flow with a video recording on the computer.

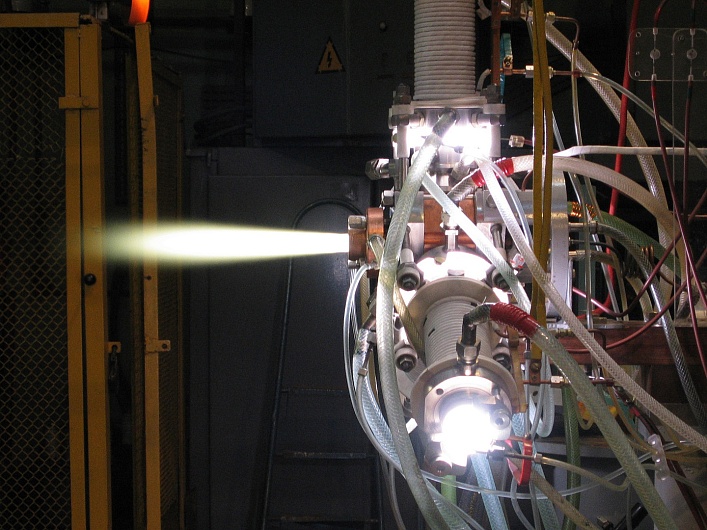

The Mach number range is from 0 up to 6.Electric arc installations (plasmatrons) facility

The test facility is intended for conducting applied scientific research in the field of thermophysics of high temperatures and to study interaction processes between high temperature gaseous flows and constructional & thermal protection materials. The Zvezda-type three-phase AC electric arc heater with a nominal power of 4MW and with a nominal power of 20 MW are two main devices of the test facility.

The following tests are carried out here:

- tests of thermal protective coatings and materials (construction materials);

- tests of heat-exchange equipment;

- tests of high temperature fittings.

Electrophysical studies facility

The facility is intended for investigation of artificial plasma formations` impact on electromagnetic waves distribution.

Climatic and thermal cycling test facility

There are two chambers at this facility.

-

Heat-cold/humidity test chamber is intended to check performance and function capabilities, lifetime and other technical characteristics at different environmental conditions. The chamber can be also used to evaluate temperature and humidity effects on equipment and structure components during entire lifetime of a product. Temperature in the chamber is kept from -750C up to +1800C.

-

A chamber for testing electronic equipment, materials, devices and other technical appliances for stability (i.e. resistance and strength) to high/low temperatures` effect on a thermoplate in vacuum. Temperature in the chamber is kept from -1500C up to +2000C.

Vibration test facility

The facility is intended to conduct tests of products for external influences.

Range of frequencies:

Vibration generator up to 3000 HzHorizontal table up to 2000 Hz

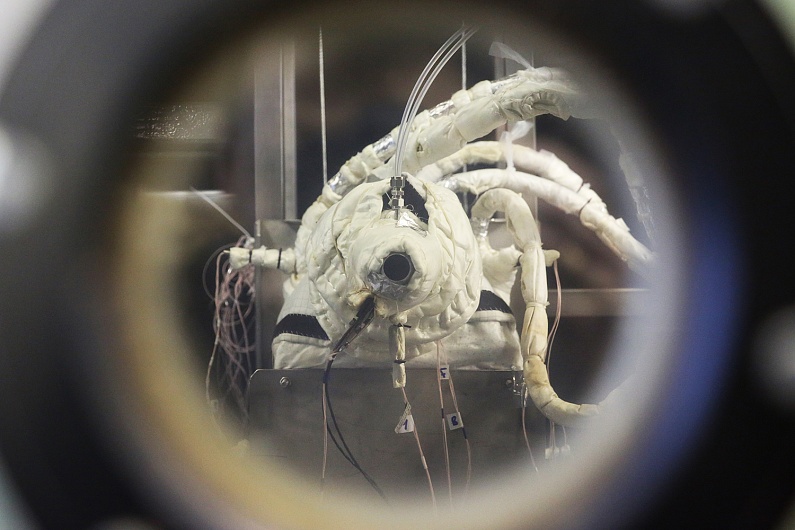

Cryogenic vacuum chamber

The chamber is equipped with two pre-chambers that allow conducting tests and replacing a product without atmosphere supply into the main unit of a vacuum chamber.

The chamber is equipped with cryogenic pumps.

Chamber`s volume is 90 m3, chamber`s diameter is 3.8 m.

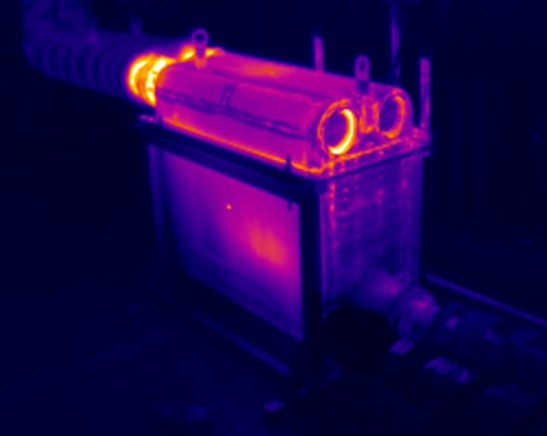

Thermal-vacuum test facility

The facility is intended for conducting thermal-vacuum tests of structure elements under the conditions close to natural ones.

The vacuum chamber`s volume is 25 m3 with a high-precision simulation of solar radiation.

Radiometric calibration of infrared devices is used for conducting tests.

Thermal-vacuum tests of equipment, thermal-vacuum and radiometric tests of structure components are carried out at the facility.

Fuel elements test facility

It is intended for testing power systems on fuel elements.

The test bench for manufacturing and testing power systems

It is intended for:

-

Assembling and testing high-temperature electrochemical batteries of different types;

-

Assembling and testing electrolyzes of space purpose together with service systems.

Facility for conducting thermophysical and lifetime tests of thermal regulation system elements

Working medium is ammonia.

Water treatment technologies test facility

The technical equipment of the test bench allows us to assembly and to test water treatment installations based on such various principles of work as reverse osmotic and ion exchange, ultra- and microfiltration, and backfilled filters.

For testing installations, the test bench is equipped with control and measuring devices as well as analytical equipment, which can record indicators of a water treatment process and can carry out research of new promising directions in this area.

Facility for conducting tests of components of turbomachinery energy conversion systems

Machinery hall is the most powerful and multifunctional test facility in the world intended for the experimental development of components of turbomachinery energy conversion systems.

Development and investigation tests of components of powerful power propulsion systems with turbo-machine energy conversion are carried out at the facility.

Test facility for thermal erosion tests of thermal protection materials

The test facility is equipped with an air-kerosene heater and consists of two installations:

-

Installation for investigation of a thermal protection material`s destruction during one-side heating in a gaseous jet in order to determine a temperature state of materials` samples and their thermal conductivity. A tested sample is heated by passing electrical current through it.

-

Installation intended for thermal cycling tests of materials in an inert medium.

The test facility for investigation of electrophysical and thermophysical characteristics of energy elements

Electrical and thermophysical research works of power supply systems are carried out at the facility.

The test bench is equipped with a charge-discharge system of lithium ion batteries (low voltage equipment, nanomechanical gyroscope accelerometer, lithium ion battery and others) as well as with a complex based on the vacuum chamber to carry out their wear tests under vacuum conditions (up to 10-3 Pa) and low temperatures (up to -100°C)